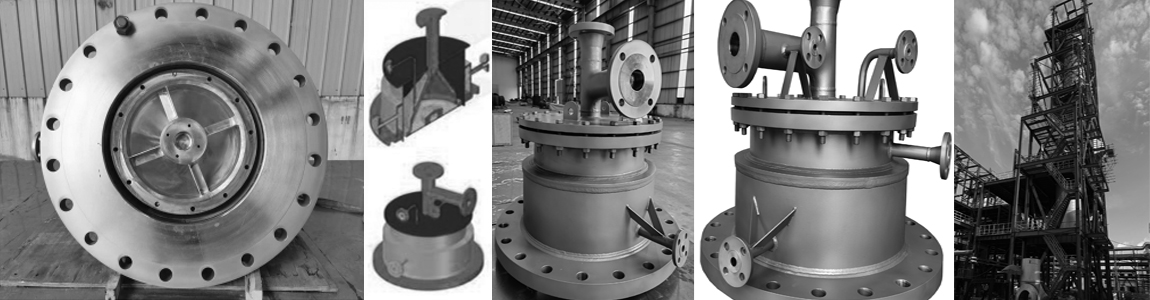

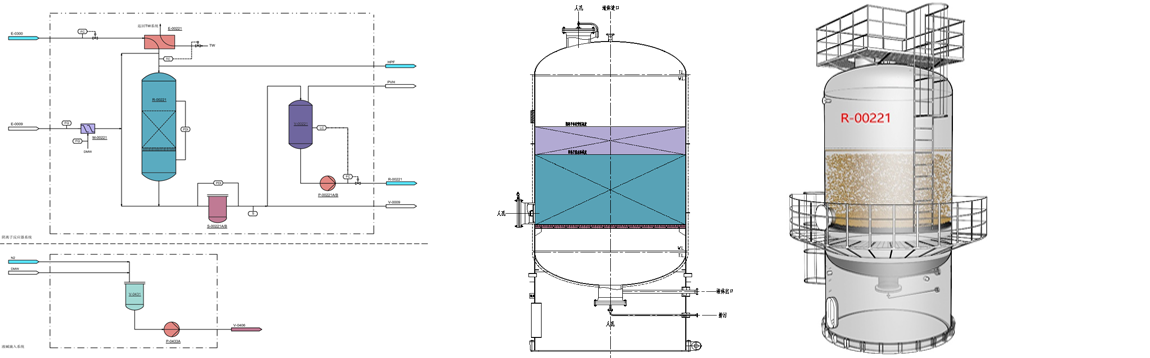

BPA (Bisphenol A) Prilling System is to atomize the heated and melted Bisphenol A liquor in the Prilling tower, and the Bisphenol A droplets are solidified after contacting with cold nitrogen to obtain bisphenol A spherical products. The main equipment of BPA (Bisphenol A) Prilling System include Prill Nozzle, Prilling Tower, BPA Dust Collector, Vibrating Screen, N2 Buffer Tank, Excessive Particle Catcher, BPA Dust Collection Drum, Circulation Pump, BPA Dust Recovery Tank, N2 Circulation Cooler, Heat Exchanger and Blower. We made research about BPA Prilling System and we have authorized by CNIPA for the Prilling Nozzle, Prilling Tower and BPA Prilling Process, please refer to the PPT for detail.

Go to BPA Prilling PPT

BPA (Bisphenol A) Prilling System including Spraying Prilling and Rotating Prilling.

Rotating Prilling

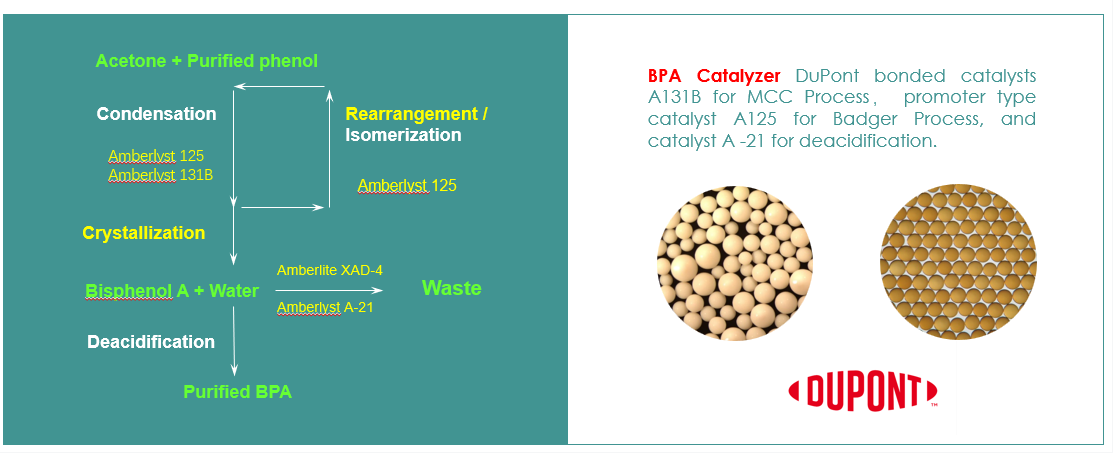

Acid Removal System composed an anion reactor system and liquid alkali drip system. It is used to remove acidic substances accumulated in the mother liquor during the production of bisphenol A, to ensure that the acidity of the mother liquor system is limited and controlled within a relatively low range, and the melting chromaticity of bisphenol A products is ≤ 10-15. The acid removal system and the anion reactor have the independent intellectual property rights.

Go to Acid Removal Technology PPT

BPA Catalyzer

The process of Polycarbonate Powder Producing is an Innovation of us in recent a couple of years, to serve the domestic clients with technical solutions & package delivery, to achieve the good Process Modification and Market Adaption of Polycarbonate Products.

Go to PC Powder Producing Technology PPT

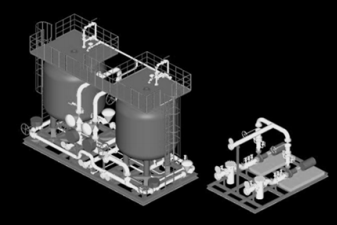

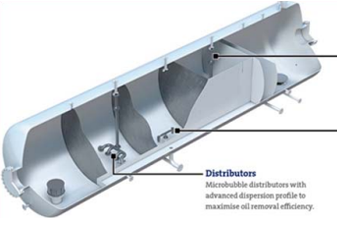

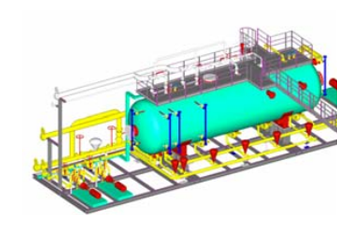

Induced Gas Flotation (IGF) is adopted from the method of jet-entrained gas jet for gas flotation.

It can greatly reduce energy consumption, simplify the over-all structure, facilitate sealing and high

efficiency to use. Induced Gas Flotation (IGF) advantages shows as below:

Induced Gas Flotation (IGF) is adopted from the method of jet-entrained gas jet for gas flotation.It can greatly reduce energy consumption, simplify the over-all structure, facilitate sealing and highefficiency to use. Induced Gas Flotation (IGF) advantages shows as below:

We made research about IGF System and we have project experiences in Middle East Market, including Khermala Oilfield, Halfaya Oilfield, please refer to the PPT for detail.

We made research about IGF System and we have project experiences in Middle East Market, including Khermala Oilfield, Halfaya Oilfield, please refer to the PPT for detail.

Go to IGF PPT

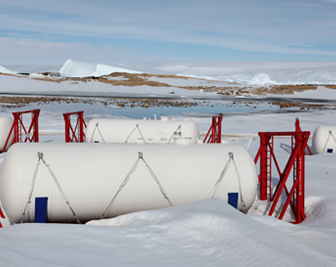

As all know, Antarctic is an extremely cold area with ice & snow covered, we built a storage tank project at

there in 2010. Many technical challenges happened because of the extremely cold temperatures, but

bring the following technology in hand after project successfully complete.

As all know, Antarctic is an extremely cold area with ice & snow covered, we built a storage tank project at there in 2010. Many technical challenges encountered because of the extremely cold temperatures, but bring the following technology in hand after project successfully delivery.

Sertus Chambers, P.O. Box 905,

Quastisky Building, Road Town,

Tortola, British Virgin Islands

+86+18611697939

Contact Person: Coco Ding

dingling@relyscience.com

www.relyscience.com

dingling@relyscience.com

www.relyscience.com